3D-printed concrete pools let you create custom, complex shapes quickly and precisely using a specialized printer that layers concrete from a digital design. This method reduces construction time, minimizes waste, and offers innovative features like waterfalls or textured surfaces. While the technology may cost more upfront, it’s durable, low-maintenance, and environmentally friendly. If you want to explore how this innovative process can transform your pool project, there’s plenty more to discover.

Key Takeaways

- 3D printing allows for complex, customized pool designs with organic shapes, waterfalls, and textured surfaces, enhancing aesthetic appeal.

- The process involves layer-by-layer extrusion of concrete from digital models, reducing construction time and material waste.

- Benefits include high precision, reduced labor costs, lower maintenance, and long-lasting, durable structures.

- Initial costs are higher due to advanced technology but can lead to savings through faster construction and less waste.

- Future trends focus on sustainable materials, automation, and smart features, making pools more eco-friendly and customizable.

How 3D Printing Works for Concrete Pools

3D printing for concrete pools involves using a specialized printer to layer material precisely according to a digital design. You start with a detailed 3D model that guides the printer’s movements. The printer then extrudes a specialized concrete mixture, depositing it in thin, controlled layers. As each layer cures, the printer moves upward, building the pool’s shape from the bottom up. This process allows for complex, customized designs that traditional methods struggle to achieve. You can incorporate curves, intricate details, and unique features directly into the digital blueprint. The precision of the printer ensures consistent layer thickness and reduces material waste. Additionally, the use of STEM principles in 3D printing enhances accuracy and enables innovative design possibilities. The ability to customize designs directly impacts the versatility and appeal of modern pool construction. Moreover, the integration of sustainable materials in the printing process can make these pools more environmentally friendly. The use of advanced construction techniques further improves the durability and longevity of 3D-printed pools. Incorporating beach-inspired features can also enhance the aesthetic appeal of these pools, blending natural environments with modern technology. Overall, 3D printing transforms pool construction by making it faster, more flexible, and capable of delivering highly detailed, innovative designs.

Benefits of Choosing a 3D-Printed Pool

Choosing a 3D-printed pool offers numerous advantages that traditional construction methods can’t easily match. First, it markedly reduces construction time, so you get your pool faster without sacrificing quality. Second, the precision of 3D printing minimizes waste and ensures consistent, high-quality results. Third, the process allows for complex designs and shapes that traditional methods struggle to achieve, giving you unique options tailored to your space. Additionally, 3D printing can lower costs by reducing labor and material waste. This innovative approach not only speeds up installation but also enhances durability and customization. The ability to create complex shapes and intricate details sets 3D-printed pools apart from conventional ones, offering more personalized options. Furthermore, the use of advanced manufacturing techniques can improve overall structural integrity and longevity. Incorporating innovative construction methods can also reduce environmental impact and support sustainable building practices. For example, 3D printing enables the use of recyclable materials, which further contributes to eco-friendly construction. Utilizing nutritional advantages from sustainable materials can also promote healthier environmental outcomes. Overall, opting for a 3D-printed pool provides efficiency, quality, and creative freedom you won’t find with traditional building techniques.

Design Flexibility and Customization Options

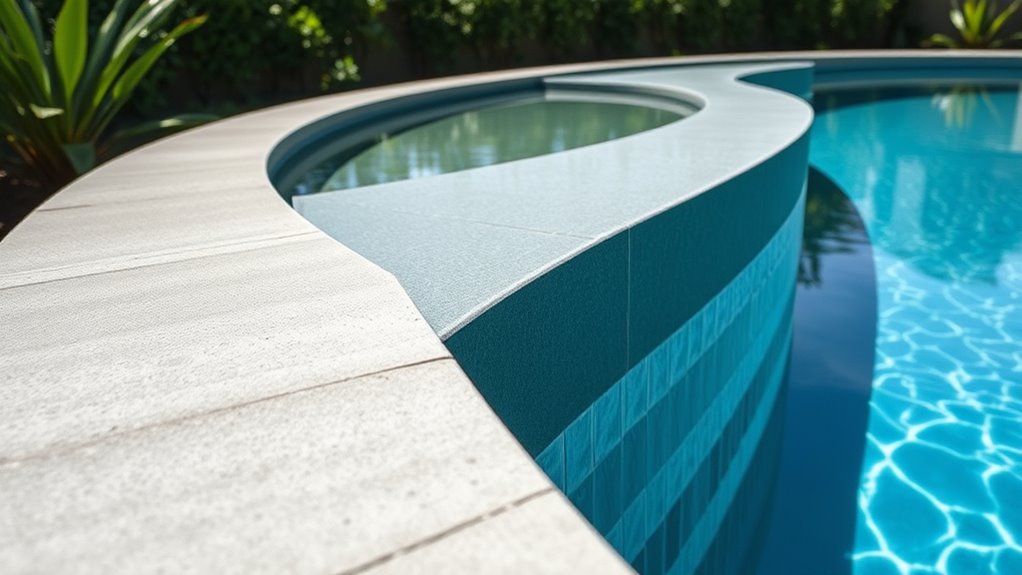

One of the most exciting benefits of 3D-printed pools is the unparalleled design flexibility they offer. You can create unique shapes, custom sizes, and intricate details that traditional pools can’t match. Want a freeform design or an integrated waterfall? No problem. The technology allows you to bring your vision to life with precise, complex features. This customization extends to features like built-in seating, textured surfaces, or personalized patterns. Here’s a quick look at some options:

| Feature | Description |

|---|---|

| Unique Shapes | Curved, organic, or geometric designs |

| Custom Patterns | Textures, logos, or decorative accents |

| Integrated Features | Seating, waterfalls, lighting elements |

This flexibility ensures your pool complements your lifestyle and aesthetic perfectly. Design versatility is a key advantage that makes 3D-printed pools stand out in the landscape of pool construction. Additionally, understanding the local sourcing of materials can help ensure the durability and sustainability of your custom pool, especially since material quality is crucial for longevity.

Construction Process and Timeline

The construction process for 3D-printed concrete pools typically begins with designing a detailed digital model, which guides the entire build. Once the design is complete, the printing begins, layer by layer, using a specialized 3D printer. This process usually takes anywhere from a few days to a couple of weeks, depending on the pool’s size and complexity. After printing, the pool may require curing time to ensure the concrete gains strength. Additionally, the use of sound vibrations can potentially enhance cellular regeneration in the curing process, promoting a stronger, more durable structure. Incorporating natural materials like prairie scenery into the finishing process can improve environmental integration and durability. Furthermore, understanding construction timelines helps in planning and managing expectations throughout the project. Considering material properties is essential for ensuring the longevity and safety of the finished pool. Finally, finishing touches like plumbing, electrical work, and waterproofing are added to complete your pool. Here’s what to expect:

- Creating a precise digital model for accurate printing.

- 3D printing the structure, which can take several days.

- Post-printing finishing and installation, spanning a few days to weeks.

Cost Considerations and Budgeting

Understanding the costs involved helps you plan effectively for your 3D-printed pool project. You’ll need to take into account initial investment expenses, ongoing maintenance, and options that save money without sacrificing quality. Exploring these factors ensures your budget aligns with your pool’s design and long-term needs. Additionally, considering cost-effective AI solutions can optimize project planning and reduce overall expenditures. Incorporating high-pressure spray technology into your planning can also help you evaluate the efficiency and potential cost savings of different construction methods. Being aware of state-specific tax laws can also influence your overall project budgeting, especially if you are considering financing options or potential tax incentives. Incorporating organic and natural materials into your project’s design choices might also offer sustainable and cost-saving benefits over time. Furthermore, understanding community engagement strategies can help garner local support and potentially access grants or incentives for sustainable construction.

Initial Investment Costs

While 3D-printed concrete pools can offer innovative design options, they usually require a higher initial investment compared to traditional pools. This upfront cost reflects several factors:

- Advanced Technology: Investing in 3D printing equipment and materials can be costly, as these are specialized and cutting-edge.

- Design Customization: Unique, complex shapes often demand extra planning and engineering, increasing project expenses.

- Labor and Expertise: Skilled technicians are essential for operating 3D printers and ensuring quality, which can raise labor costs.

- Additional considerations include sourcing durable materials suitable for pool construction and navigating any local regulations or permits associated with innovative building methods.

Although the initial investment is higher, these pools can save money over time through reduced construction time and minimized waste. Still, you should carefully analyze your budget to determine if the benefits outweigh the upfront costs.

Long-term Maintenance Expenses

Long-term maintenance expenses for 3D-printed concrete pools tend to be lower than those of traditional pools due to their durable construction and seamless design. The solid, monolithic structure reduces the likelihood of cracks, leaks, and structural issues that often require costly repairs. Additionally, the smooth surface minimizes algae buildup and simplifies cleaning, cutting your ongoing maintenance time and costs. You’ll also save on chemical usage because the consistent surface helps maintain water balance more effectively. Unlike traditional pools, the absence of joints or seams means fewer places for debris to accumulate. Overall, you’ll find that these pools demand less frequent repairs and upkeep, helping you keep maintenance costs predictable and manageable over the years.

Cost-Effective Design Options

Choosing the right design options for your 3D-printed concrete pool can substantially influence your overall budget. To save costs, consider these options:

- Simplify the shape: Opt for a basic, streamlined design rather than complex curves or intricate features, reducing printing time and material use.

- Limit custom features: Focus on essential elements and avoid luxury add-ons that increase costs, keeping your project within budget.

- Use standard sizes: Choosing a standard or smaller pool size can cut material and labor expenses significantly.

Durability and Maintenance of 3D-Printed Pools

The durability of 3D-printed concrete pools largely depends on the quality of the materials and printing process used. High-quality mix designs with proper additives help enhance strength and resistance to cracking. The precision of the printing process ensures uniform layer deposition, reducing weak spots. Regular maintenance, like inspecting for cracks, cleaning, and sealing, is vital to prolong the pool’s lifespan. Since 3D-printed pools often have complex shapes, you should pay attention to joints and edges, which may be more vulnerable. Using appropriate sealants and performing routine upkeep can prevent water infiltration and deterioration. Keep an eye on surface wear and address issues promptly to maintain structural integrity. Proper maintenance not only extends your pool’s life but also keeps it looking appealing and functioning at its best.

Environmental Impact and Sustainability

3D-printed concrete pools can substantially reduce environmental impact compared to traditional construction methods by minimizing material waste and allowing for more precise use of resources. This efficiency means fewer raw materials are needed, reducing extraction and transportation emissions. Additionally, the controlled printing process lowers the risk of excess material disposal, cutting down on landfill waste. You also benefit from the potential for using eco-friendly, recycled, or locally sourced materials, further enhancing sustainability.

Here are three key environmental benefits:

- Reduced material waste through precise printing.

- Lower carbon footprint from decreased transportation needs.

- Opportunity to incorporate sustainable, recycled materials.

Potential Challenges and Limitations

While 3D-printed concrete pools offer many advantages, they also face several challenges that can limit their widespread adoption. One major issue is ensuring structural integrity and durability, as the technology is still evolving, and some designs may not withstand long-term wear or environmental stresses. Additionally, the printing process can be time-consuming and costly, especially for complex shapes or larger pools, which may deter homeowners or builders. Limited material options and consistency issues also pose problems, as not all concrete mixes are suitable for 3D printing. Regulatory hurdles and building codes can slow approval processes, making it harder to implement this technology on a broad scale. Finally, skilled labor and specialized equipment are required, which can increase upfront costs and limit access.

Choosing a Provider and Quality Assurance

When selecting a provider for your 3D-printed pool, you need to check their credentials and certifications to make certain they meet industry standards. It’s also essential to verify that they use high-quality materials and maintain transparency throughout the construction process. Doing so helps guarantee your pool’s durability and that the project adheres to safety and quality benchmarks.

Provider Credentials and Certification

Choosing the right provider is essential to guarantee your concrete pool is built to the highest standards. You want a team with proven credentials and recognized certifications that demonstrate their expertise in 3D-printed concrete construction.

To guarantee quality and reliability, look for these key indicators:

- Industry Certifications: Confirm they hold certifications from reputable organizations, indicating adherence to safety and quality standards.

- Experienced Workforce: Verify that their team has specialized training in 3D printing technology and concrete application.

- Proven Track Record: Review their portfolio for completed projects similar to yours, and ask for references to validate their work.

These steps help you select a provider committed to delivering a durable, high-quality pool that meets all safety and design expectations.

Material Quality Standards

Ensuring the material quality standards of your 3D-printed concrete pool is essential for long-lasting durability and safety. When selecting a provider, verify they adhere to strict industry standards and use high-grade materials. Ask for detailed documentation on the concrete mix, including compressive strength, durability, and resistance to environmental factors. Quality assurance should involve rigorous testing and inspection throughout the printing process, not just at the end. Don’t hesitate to request samples or certifications that confirm the materials meet recognized safety and performance benchmarks. A reputable provider will be transparent about their sourcing and quality control procedures. Prioritizing these standards helps prevent issues like cracking, leaks, and structural failure, ensuring your pool remains safe and durable over time.

Construction Process Transparency

To make sure your 3D-printed concrete pool meets quality and safety standards, it’s essential to evaluate a provider’s construction process transparency. This helps you understand how your pool is built and ensures accountability. Here are three key things to look for:

- Clear documentation of each stage, from design to finishing, so you know what’s happening at every step.

- Open communication channels where you can ask questions and receive updates regularly.

- Proven quality control procedures, including inspections and testing, to catch issues early and maintain standards.

Future Trends in 3D-Printed Pool Technology

How will 3D-printed pool technology evolve in the coming years? Expect rapid innovation driven by advances in materials and automation. You’ll see more sustainable options, like eco-friendly concrete mixes and recyclable materials, reducing environmental impact. As robotic printers become more precise, you’ll enjoy faster build times and complex designs that were previously impossible. Integration of smart technology will allow pools to adapt to your preferences automatically, enhancing user experience. The table below highlights key future trends:

| Trend | Impact |

|---|---|

| Enhanced Material Durability | Longer-lasting, maintenance-free pools |

| Increased Customization | Unique, personalized designs |

| Automation & AI | Faster, more efficient construction |

| Eco-friendly Materials | Sustainable, low-carbon footprint |

| Smart Pool Integration | Automated controls and monitoring |

These developments will revolutionize how you design, build, and enjoy your pool.

Frequently Asked Questions

How Long Does a 3d-Printed Concrete Pool Typically Last?

You’re wondering how long a 3D-printed concrete pool lasts. Generally, these pools can last 50 years or more with proper maintenance. The durability depends on the quality of the materials used and how well you care for it over time. Regular cleaning, inspections, and repairs help extend its lifespan. Since 3D printing creates precise, strong structures, your pool should remain functional and attractive for decades.

Are 3d-Printed Pools Safe for Children and Pets?

Imagine a sunny afternoon, children and pets splashing happily in a pool. You might wonder if a 3D-printed concrete pool is safe for them. Rest assured, these pools are designed with safety in mind, using durable, non-toxic materials. When properly maintained and installed by professionals, they provide a secure environment for kids and pets to enjoy the water, just like traditional pools.

What Maintenance Is Required for 3d-Printed Concrete Pools?

You need to regularly clean your 3D-printed concrete pool to prevent algae and dirt buildup. Check the chemical levels, like pH and chlorine, weekly to keep the water balanced. Inspect the structural integrity for any cracks or damage, especially after freezing temperatures. It’s also important to maintain the pool’s surface by sealing it periodically to protect against wear. Proper upkeep guarantees your pool remains safe, durable, and inviting year-round.

Can Existing Pools Be Retrofitted With 3D Printing Technology?

You can retrofit existing pools with 3D printing technology, but it depends on your pool’s current condition and structure. The process involves evaluating the pool’s integrity, planning the design, and integrating new printed components. You’ll need professionals to guarantee compatibility and safety. While not always straightforward, retrofitting offers a modern way to upgrade your pool, making it more durable and customizable without full excavation or replacement.

How Do Weather Conditions Affect the Construction Process?

Weather conditions play a vital role in your construction process. If it’s too cold, the concrete may not set properly, causing delays or weak spots. Rain can wash away materials or cause water to seep into the structure. Wind can blow debris into the mix or disrupt work schedules. You should plan your construction around favorable weather, or use protective measures like coverings and heated enclosures to guarantee quality and safety.

Conclusion

As you explore 3D-printed concrete pools, you’ll find they’re revolutionizing backyard design with up to 50% faster construction times and significant cost savings. This innovative technology offers unmatched customization and sustainability benefits, making it a smart choice for modern homeowners. Keep in mind, the industry is rapidly evolving; staying informed guarantees you get the best quality and latest advancements. Embrace the future of pool building—your perfect backyard oasis is closer than you think.