To quiet a noisy pump pad, start by pinpointing the noise source and check for loose components or vibrations. Use vibration isolation pads and mounts with dampening materials like rubber to absorb shocks. Apply soundproofing layers, such as foam or rubber mats, directly onto the surface, and consider building barriers or enclosures to reflect and block sound waves. Regular maintenance guarantees parts stay secure and quiet. Keep exploring for more effective techniques to silence your pump profoundly.

Key Takeaways

- Place vibration-dampening pads or rubber mounts beneath the pump to isolate noise and reduce vibration transfer.

- Apply dense soundproofing materials like foam, rubber, or vinyl directly to the pump or surrounding enclosure for sound absorption.

- Construct barriers with dense materials such as concrete or brick around the pump to reflect and block sound waves.

- Use layered soundproofing techniques, combining damping pads with enclosures and sound-absorbing linings for maximum noise reduction.

- Regularly inspect and tighten mounting hardware, replace worn mounts, and maintain the pump to prevent rattling and operational noise.

Identifying the Main Sources of Noise

To effectively reduce noise from your pump pad, you first need to identify the main sources of sound. Start by listening closely while the pump runs, noting where the loudest noises come from. Is it the motor, the vibrations, or the water flow? Feel for vibrations or rattling that could be causing additional noise. Check if the pump’s mounting surface amplifies sound, or if parts are loose and vibrating. Sometimes, noise stems from the pump hitting nearby surfaces or components inside the system. By pinpointing whether the noise is mechanical, structural, or fluid-related, you can develop a targeted approach to quiet it down. Proper sound insulation techniques can significantly decrease noise levels. Being aware of symptoms of breast cancer can help in early detection, much like identifying the root cause of noise early on allows for more effective noise reduction. Recognizing vibration sources and addressing them promptly can prevent further noise issues and prolong the lifespan of your pump. Additionally, inspecting the equipment’s installation can reveal if improper setup is contributing to excess noise. Understanding vibration analysis can further aid in diagnosing and mitigating noise problems effectively. Identifying the true sources allows you to focus your efforts where they’ll make the biggest difference.

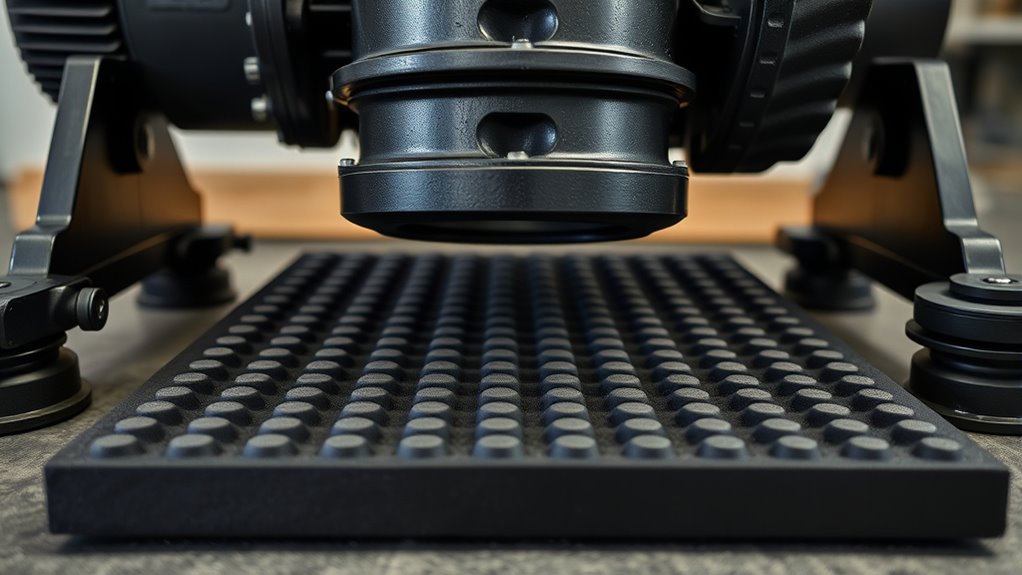

Using Isolation Pads and Mounts

Using isolation pads and mounts can considerably reduce the noise and vibrations from your pump pad. Choosing the right materials and installing them correctly guarantees effective vibration absorption. When done right, these tools can make a noticeable difference in quieting your setup. Incorporating yoga equipment such as specialized vibration-dampening mats can further enhance noise reduction and promote a more stable, quiet environment. Selecting pads with HEPA filtration qualities ensures even finer control over airborne particles generated by vibrations, improving overall air quality around your setup. Understanding material properties of the pads can help in selecting the most effective options for your specific needs. Knowing about AI in Business can inspire innovative approaches to optimizing equipment setups and noise control solutions. Proper understanding of local laws and resources can also assist in optimizing your setup for safety and efficiency.

Material Effectiveness

Selecting the right isolation pads and mounts can substantially reduce the noise transmitted from a noisy pump pad. Material effectiveness depends on factors like density, damping ability, and resilience. Heavier, denser materials absorb vibrations better, preventing them from transferring to surrounding surfaces. Soft mounts offer more damping but may compress over time, reducing effectiveness. Rigid mounts can limit movement but might transmit vibrations if not chosen carefully. Use the table below to compare materials:

| Material | Damping Ability | Durability |

|---|---|---|

| Rubber | High | Long-lasting |

| Foam | Moderate | Medium |

| Sorbothane | Very High | Very Durable |

Choosing the right combination ensures maximum noise reduction and long-term performance. Additionally, considering material properties can help optimize vibration control for specific applications. For example, understanding vibration damping can lead to better material selection and improved noise mitigation. Implementing proper vibration isolation techniques is crucial for achieving effective soundproofing, especially when dealing with vibration transfer between equipment and surrounding structures. Using appropriate fire safety measures in the context of vibration and noise control can also prevent potential hazards.

Proper Installation Tips

Proper installation of isolation pads and mounts is key to maximizing their noise-reducing benefits. First, ensure the surface where you place the pads is clean and level. Position the pads directly under the pump’s mounting points, avoiding gaps or misalignment. Use the right size and type of pads recommended by the manufacturer to guarantee proper support and cushioning. Secure mounts firmly but avoid overtightening, which can transfer vibrations instead of dampening them. Check that the pads stay in place during operation, as shifting can reduce effectiveness. Keep cables and other components clear of the mounts to prevent interference. Regularly inspect the installation to ensure everything remains secure and effective over time. Proper setup ensures ideal vibration isolation and quieter pump operation.

Vibration Absorption

Isolation pads and mounts effectively absorb vibrations from the pump, preventing them from transferring to surrounding structures. When you place these pads beneath your pump, they act as a buffer, dampening the intensity of vibrations. Mounts designed with vibration-dampening materials further reduce noise by isolating the pump from its mounting surface. This setup not only minimizes the noise transmitted through walls and floors but also protects nearby equipment from potential damage caused by constant vibration. To maximize effectiveness, verify the pads and mounts are appropriately sized for your pump’s weight and operational weight. Regularly check for wear or compression of the pads, replacing them as needed. Proper vibration absorption is a simple, cost-effective way to keep your pump quieter and extend its lifespan. Incorporating vibration-dampening materials can further enhance noise reduction by absorbing residual vibrations more effectively. Wall organization systems can also contribute to a quieter environment by reducing clutter and creating a more orderly space. Additionally, understanding the affairs that can cause emotional distress highlights the importance of maintaining a peaceful environment, both emotionally and physically. Incorporating air purifiers in the workspace can help improve air quality and further promote a calm, healthy setting.

Applying Soundproofing Materials to the Surface

Applying soundproofing materials to the surface is a crucial step in reducing noise from your pump pad. Start by cleaning the surface thoroughly to remove dirt, dust, and grease, ensuring ideal adhesion. Choose a dense, flexible material like rubber mats, foam panels, or mass-loaded vinyl to absorb and block sound. Cut the material to fit the pad’s dimensions, then securely attach it using adhesive, screws, or double-sided tape. Make sure there are no gaps or overlaps that could allow sound to escape. For added effectiveness, layer multiple materials or combine with other soundproofing techniques. Proper application creates a barrier that dampens vibrations and prevents noise from traveling through the surface, making your pump pad noticeably quieter. Incorporating soundproofing techniques can further enhance noise reduction and improve overall effectiveness. Additionally, understanding the role of sound absorption in soundproofing can help you select the most suitable materials for optimal results. Considering the types of soundproofing materials available can guide you in choosing the best options for your specific needs. Using soundproofing layers strategically can also contribute to more comprehensive noise mitigation.

Building Barriers and Enclosures for Noise Reflection

Building barriers and enclosures around your pump pad can considerably reflect sound waves away from nearby areas, reducing overall noise levels. By creating physical obstacles, you prevent sound from dispersing freely into sensitive zones. To maximize effectiveness, consider these options:

- Use dense materials like concrete or brick to form solid walls that reflect sound waves efficiently.

- Incorporate curved or angled surfaces to direct sound upward or away from noise-sensitive areas.

- Build enclosures with sound-absorbing linings inside to prevent sound from bouncing within the barrier itself.

These strategies help contain and reflect noise, making your pump pad operation less disruptive. Properly designed barriers not only reflect sound but also serve as visual shields, improving safety and aesthetics around your equipment.

Incorporating Vibration Damping Techniques

Since vibrations from your pump can transmit sound and amplify noise, incorporating vibration damping techniques is essential for quieter operation. Start by attaching rubber or foam mounts between the pump and its base to absorb shocks and reduce vibration transfer. Using resilient pads under the pump helps isolate vibrations from the surrounding structure, preventing noise from spreading. Consider adding mass to the pump’s mounting surface with dense materials like lead or concrete to limit movement. You can also install vibration isolators or dampers designed specifically for pumps, which absorb energy before it transmits into the environment. Regularly checking and tightening mounting bolts ensures vibrations don’t increase over time. These methods work together to minimize the vibration transmitted, dramatically reducing noise levels on your pump pad.

Regular Maintenance and Upgrades for Reduced Noise

Regular maintenance and timely upgrades are essential for keeping your pump operating quietly. When you stay on top of servicing, you prevent parts from wearing out prematurely and reduce unnecessary noise. Upgrading components can also make a significant difference in sound levels. Here are three key actions:

Regular maintenance and upgrades keep your pump quiet and efficient.

- Inspect and tighten all mounting bolts regularly to minimize vibrations that cause noise.

- Replace worn-out bearings or seals promptly to prevent rattling and reduce operational hum.

- Upgrade to quieter, modern pump models or add soundproof enclosures when necessary for a substantial noise reduction.

Frequently Asked Questions

Can Specific Pump Models Be Inherently Quieter Than Others?

You might wonder if some pump models are quieter by nature. Yes, certain pumps are designed with noise reduction features, such as better insulation or quieter motors. When choosing a pump, look for models labeled as “quiet” or “low-noise.” Your choices can substantially impact noise levels, making your setup more peaceful. Researching specific models helps guarantee you select one that operates quietly, reducing the need for additional acoustic tricks.

Are There Eco-Friendly Soundproofing Options Available?

Think of eco-friendly soundproofing options as a cozy blanket for your pump pad, helping it stay quiet without harming the environment. You can choose natural materials like recycled denim or cork, which absorb noise effectively. Green adhesives and biodegradable barriers also work well. These eco-friendly solutions not only hush the noise but also keep your space sustainable, making your pump pad’s silence a win for both you and the planet.

How Do Ambient Room Conditions Affect Pump Noise Levels?

Ambient room conditions play a significant role in how loud your pump sounds. If the room is too cold or humid, materials can expand or contract, amplifying noise. Hard surfaces reflect sound waves, increasing noise levels, while soft furnishings absorb them. You can reduce pump noise by controlling room temperature, adding carpets or curtains, and sealing gaps around windows and doors, creating a quieter environment for your equipment.

What Safety Precautions Should Be Taken During Noise Reduction Modifications?

When you’re reducing noise, safety is key. You should always wear hearing protection and gloves to prevent injury from loud sounds or sharp edges. Turn off and unplug the pump before making any modifications to avoid electrical hazards. Work in a well-ventilated area and follow manufacturer instructions carefully. If you’re unsure, consult a professional to make certain you’re taking proper safety precautions throughout the process.

Can Noise Reduction Techniques Extend the Lifespan of the Pump?

You might wonder if noise reduction techniques can help your pump last longer. While primarily aimed at decreasing noise, these methods often reduce vibrations and stress on the pump’s components. By minimizing wear and tear, you can potentially extend its lifespan. Regular maintenance combined with noise control strategies keeps your pump operating smoothly, preventing early failures and saving you money on repairs or replacements over time.

Conclusion

Think of your pump pad as a quiet lake, where ripples and echoes disturb peace. By applying these acoustic tricks, you become the gentle hand calming those waves, transforming chaos into calm. Each step acts like a pebble, creating a ripple of silence that spreads outward. With patience and effort, you craft a serene oasis amidst the noise, turning your pump pad into a tranquil haven where sound fades, leaving only the stillness of a peaceful, undisturbed pond.